Who we are

Innovation, upcycling, and sustainability

Innovation, upcycling, and sustainability

It all started in 2017, when we had a simple yet revolutionary idea: recovering and valorizing plant byproducts, transforming them through a low-temperature drying process.

Our goal? To give new life to discarded products and finally make the agri-food chain circular.

A project that began at the University of Modena and Reggio Emilia, when we realized that the market lacked food products capable of meeting the needs of those who, like us, have always been attentive to sustainability and the nutritional and sensorial quality of their food.

To do this, we needed to do something concrete that could change the agri-food sector. Therefore, we decided to found the startup Packtin, with the intention of developing a unique, circular upcycling process that recovers and valorizes plant-based byproducts and transforms them into innovative flours. Our project, however, is constantly evolving.

Today, thanks to the experience we gained at Packtin, we have launched Reflavor, a brand you can trust if you’re looking for flours that are not only good for your health, but also for the planet. Because a more circular and sustainable future is accessible to everyone. You just have to make the right choice.

Innovation, upcycling, and sustainability

It all started in 2017, when we had a simple yet revolutionary idea: recovering and valorizing plant byproducts, transforming them through a low-temperature drying process.

Our goal? To give new life to discarded products and finally make the agri-food chain circular.

A project that began at the University of Modena and Reggio Emilia, when we realized that the market lacked food products capable of meeting the needs of those who, like us, have always been attentive to sustainability and the nutritional and sensorial quality of their food.

To do this, we needed to do something concrete that could change the agri-food sector. Therefore, we decided to found the startup Packtin, with the intention of developing a unique, circular upcycling process that recovers and valorizes plant-based byproducts and transforms them into innovative flours. Our project, however, is constantly evolving.

Today, thanks to the experience we gained at Packtin, we have launched Reflavor, a brand you can trust if you’re looking for flours that are not only good for your health, but also for the planet. Because a more circular and sustainable future is accessible to everyone. You just have to make the right choice.

Our values

We have always believed that the health of the planet goes hand in hand with the well-being of all of us.

Mission

Our mission is to help reduce food waste and make the agri-food supply chain circular. How? By valorizing by-products, often discarded today, to obtain new raw materials and offer high-quality, healthy, and sustainable foods to the market.

Vision

Our vision is to be the benchmark for innovation in the agri-food sector, inspiring Italian and European companies to adopt circular production models that optimize the use of our available natural resources.

Sustainability

We apply sustainability and circularity to the raw materials we choose and the production process we use. Our advanced low-temperature drying technology reduces energy consumption and greenhouse gas emissions and allows for both the recovery and reuse of water extracted from raw materials.

Raw

Materials

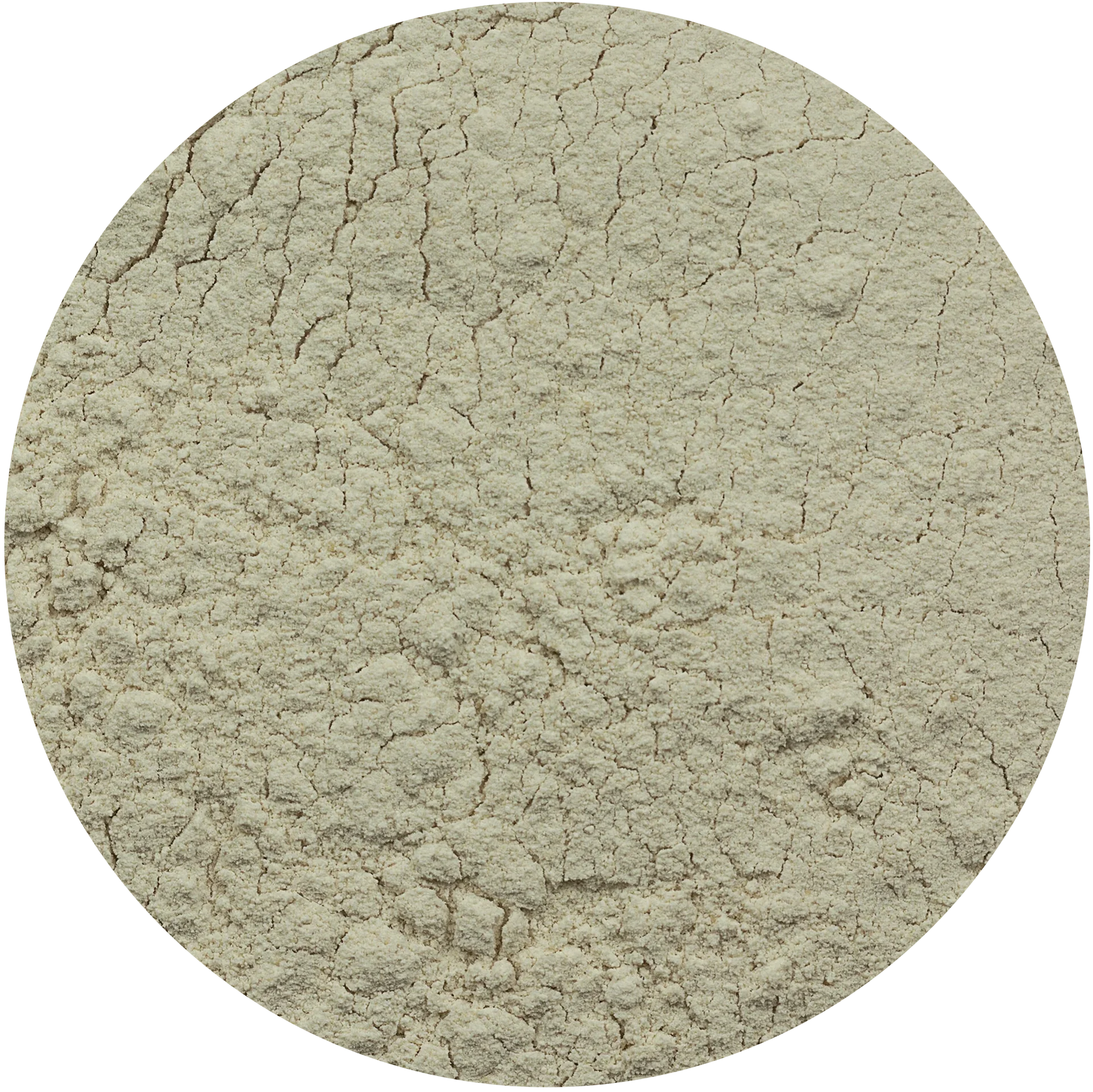

To create our upcycled flours, we use only plant-based by-products, still rich in valuable molecules. Furthermore, thanks to low-temperature drying, we preserve 100% of the product’s nutritional and organoleptic properties, preserving its natural color and distinctive aromas.

Did you know, for example, that orange peels contain more vitamin C than orange pulp?

Using by-products as raw materials reduces the use of new natural resources, reduces food waste, and minimizes environmental impact.

For every kg of flour we produce, we recover up to 5 kg of raw materials, which would otherwise be wasted!

Our process

Compared to traditional drying methods, ours stands out for being highly sustainable because it uses no gas and does not emit CO₂ or other greenhouse gases. Furthermore, it consumes little energy and allows us to recover all the water extracted from the by-products and reuse it.

ORANGE

TOMATO

GINGER

RICE

OAT

DRYING

A low temperature process allows to preserve all the nutritional properties of raw materials.

MILLING

The dried product is milled in specific machinery.

SIEVING

Final step where different particles size are separated to answer different customer needs.

FLOUR

Orange peel

FLOUR

Tomato peel

FLOUR

Ginger

FLOUR

Rice okara

FLOUR

Oat Okara

Our process

Compared to traditional drying methods, ours stands out for being highly sustainable because it uses no gas and does not emit CO₂ or other greenhouse gases. Furthermore, it consumes little energy and allows us to recover all the water extracted from the by-products and reuse it.

DRYING

A low temperature process allows to preserve all the nutritional properties of raw materials.

MILLING

The dried product is milled in specific machinery.

SIEVING

Final step where different particles size are separated to answer different customer needs.