B2B

Reflavor for Food Industry Operators

Reflavor is the ideal partner for bakers, pizza makers, gelato makers, pastry chefs, and all other food industry operators looking to use sustainable ingredients. Our upcycled flours, made with raw materials recovered from selected food by-products, are the result of a production process that combines sustainability, quality, and respect for the environment.

Our flours preserve all the nutritional properties of the ingredients, ensuring excellent results for bread, pizza, gelato, and sweet and savory preparations. Furthermore, we work directly with operators to understand their needs, offering tailored support and ensuring each customer receives the attention they deserve.

With us, you can make a difference: creating tasty and nutritious foods while helping to reduce food waste.

The benefits of our flours

Rich in fiber

Our flours are rich in fiber and suitable for diabetics and those with high cholesterol.

Rich in protein

Rice and oat okara flours are rich in protein and particularly suitable for athletes.

Gluten-free

Our flours are naturally gluten-free (with the exception of oat okara).

Plant-based

Flours that meet the needs of specific diets, such as vegetarians and vegans.

Lycopene

Tomato peel flour contains lycopene, a carotenoid with antioxidant properties.

Vitamin C

Orange peel flour contains vitamin C, an antioxidant that supports the immune system.

Gingerols and shogaols

Ginger flour contains gingerols and shogaols, compounds known for their digestive properties.

Raw

Materials

To create our upcycled flours, we use only plant-based by-products, still rich in valuable molecules. Furthermore, thanks to low-temperature drying, we preserve 100% of the product’s nutritional and organoleptic properties, preserving its natural color and distinctive aromas. Did you know, for example, that orange peels contain more vitamin C than orange pulp?

Using by-products as raw materials reduces the use of new natural resources, reduces food waste, and minimizes environmental impact.

For every kg of flour we produce, we recover up to 5 kg of raw materials, which would otherwise be wasted!

Our process

Compared to traditional drying methods, ours stands out for being highly sustainable because it uses no gas and does not emit CO₂ or other greenhouse gases. Furthermore, it consumes little energy and allows us to recover all the water extracted from the by-products and reuse it.

ORANGE

TOMATO

GINGER

RICE

OAT

DRYING

A low temperature process allows to preserve all the nutritional properties of raw materials.

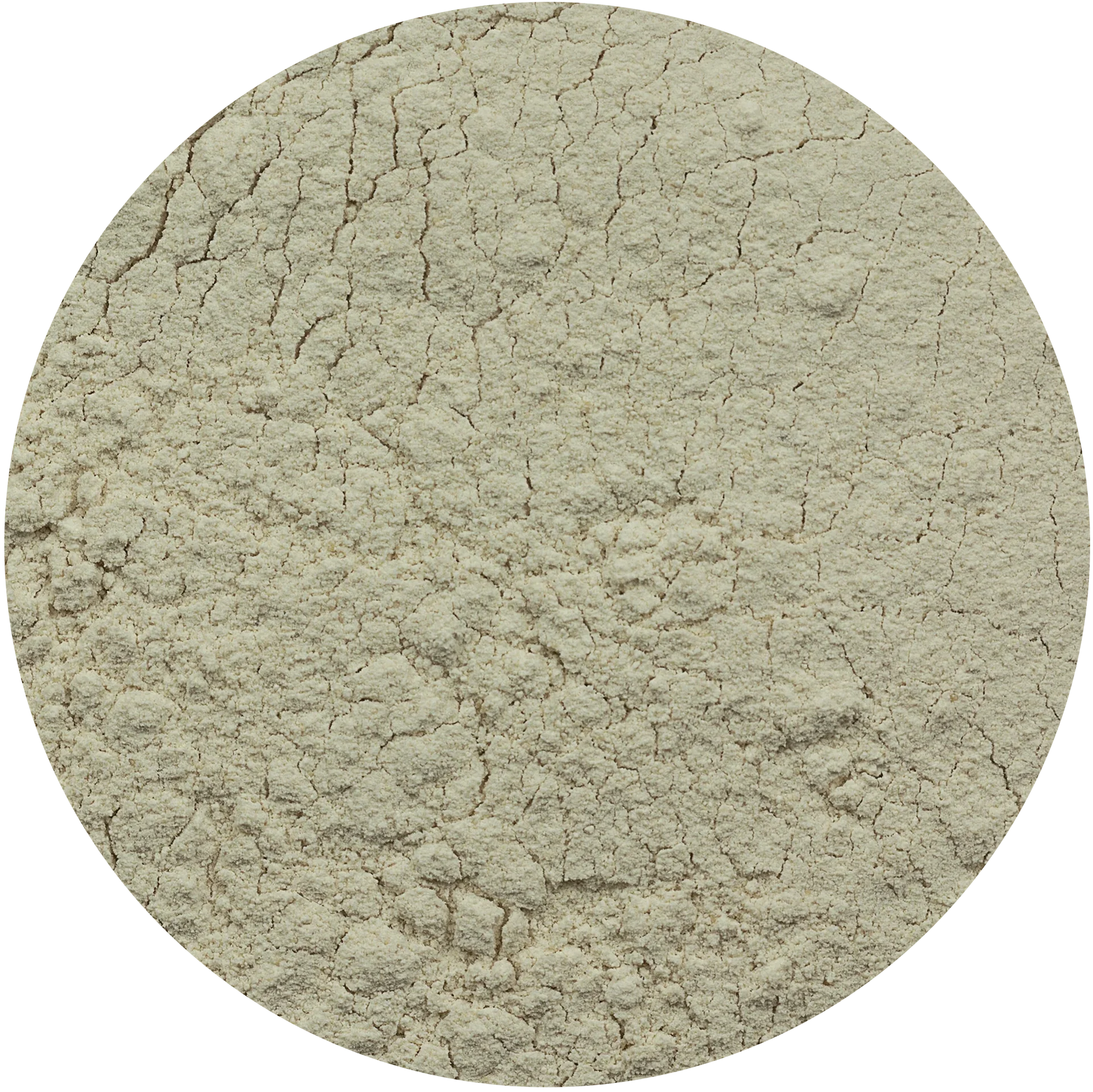

MILLING

The dried product is milled in specific machinery.

SIEVING

Final step where different particles size are separated to answer different customer needs.

FLOUR

Orange peel

FLOUR

Tomato peel

FLOUR

Ginger

FLOUR

Rice okara

FLOUR

Oat Okara

Our process

Compared to traditional drying methods, ours stands out for being highly sustainable because it uses no gas and does not emit CO₂ or other greenhouse gases. Furthermore, it consumes little energy and allows us to recover all the water extracted from the by-products and reuse it.

DRYING

A low temperature process allows to preserve all the nutritional properties of raw materials.

MILLING

The dried product is milled in specific machinery.

SIEVING

Final step where different particles size are separated to answer different customer needs.